More choices for more people.

Velocity's high-quality products in a wide range of variations have become a function in themselves for cyclists and have enriched their world. Velocity's philosophy, which began with a simple bottle cage in 1989, continues to be followed by cyclists around the world, and you are sure to find the best-fitting high-performance rim for your bike in their diverse lineup.

-RIM TECHNOLOGY-

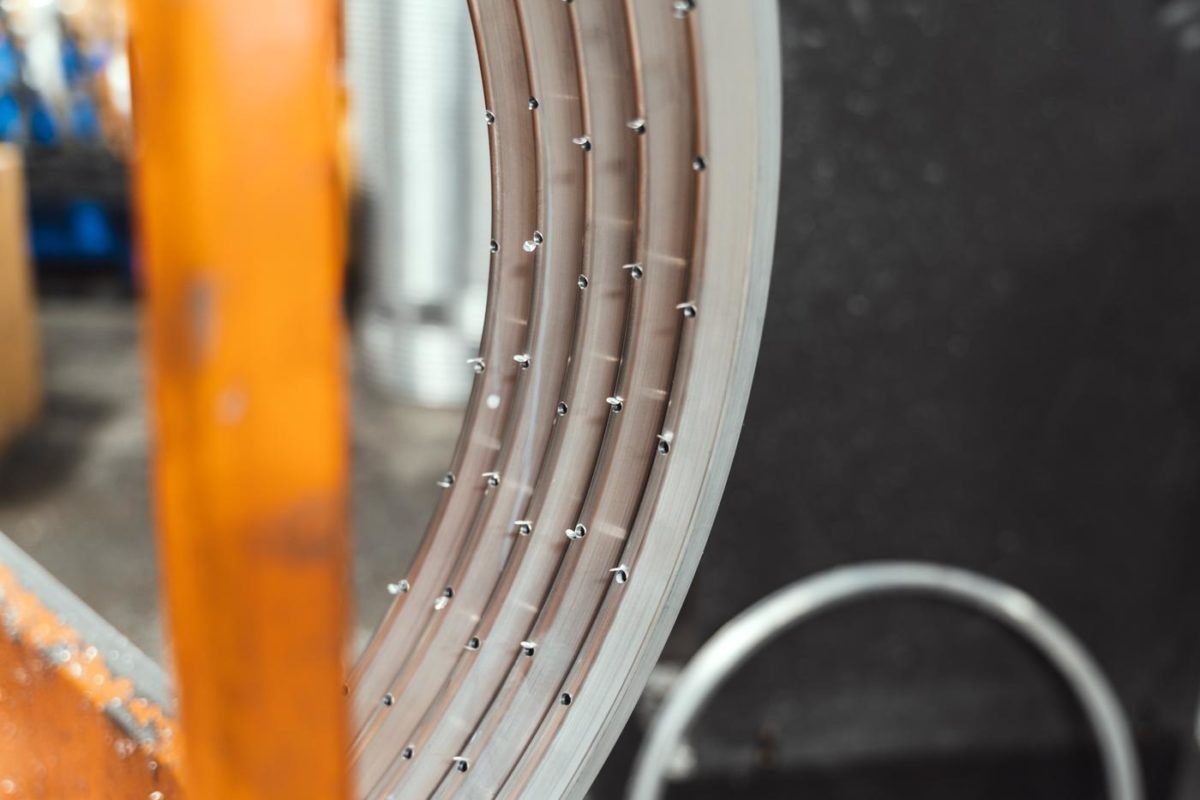

Eyelet & Drill Angle

Eyelets are used on the rim of the box-shaped cross section to provide strength to the normally thin extruded portion of the rim. Rims currently using eyelets are Atlas is the only rim that uses eyelets.

Aero section rims do not require the use of eyelets for strength, as additional aluminum is used to provide strength to the spoke bed portion of the rim.

*Box section rim: rim designed with a traditional shallow rectangular shape

*Aero section rim: rim designed with slanted sides

Some people think that eyelets help wheel fabrication by creating smooth sockets for the spoke nipples to turn, but VELOCITY drills all rims, with or without eyelets, to allow for smooth spoke adjustment.

The exit angle of the spoke holes is approximately 4 degrees, and every other spoke hole is drilled so that the left and right flange bias alternates.

joining technology

VELOCITY uses a proprietary sleeve-joining process to create its rims.

This process uses a joiner extrusion that fits perfectly into the rim's internal cavity and is adjusted so that the rim is perfectly round and flat before being chemically welded. Since the joints are not weak and brittle as with arc or resistance welding, the strength properties of the aluminum in the joints are maintained and the rim can be produced with high reliability.

Recommended spoke tension

It is recommended that spoke tension be assembled at 110 kgf to 130 kgf.

It varies slightly from rim to rim, but a good wheel builder will be able to find the best tension that the rim will tolerate while maintaining radial and lateral roundness.

Suggestion of optimal number of spokes

Considering the rider's weight and equipment, we recommend 32 front and rear spokes each for riders weighing 90 to 103 kg, 36 front and rear spokes each for riders weighing 104 to 117 kg, and 36 front and 40 rear spokes for riders weighing 117 to 136 kg. We recommend 40 spokes for the front and 40 spokes for the rear. These are just a brief guide to show you what wheelsets are best for you. If you have any questions about wheelsets, please do not hesitate to contact us.

Sidewall machining(MSW)

Designed for rim brakes, painted or anodized rims offer machined sidewalls (MSW) for superior braking performance.

Material is removed wherever possible to achieve a completely flat, raw aluminum braking surface. Silver and polished rims do not need to be machined, so we choose not to machine the sidewalls, even for rim brakes.

These finishes provide excellent braking performance and are not scratched by wear. The lack of machining results in a longer service life for the sidewalls of the rim.

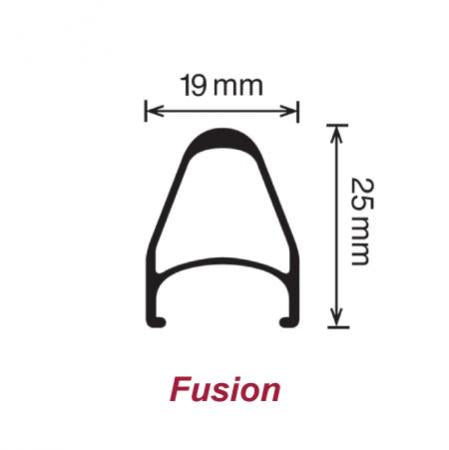

tubeless design

These tubeless-ready rims feature a modified web shape to allow for the setup of tubeless tires. These designs have tight tolerances at the bead of the rim, with or without a tube, to ensure proper tire fitment. tongue tape is required.

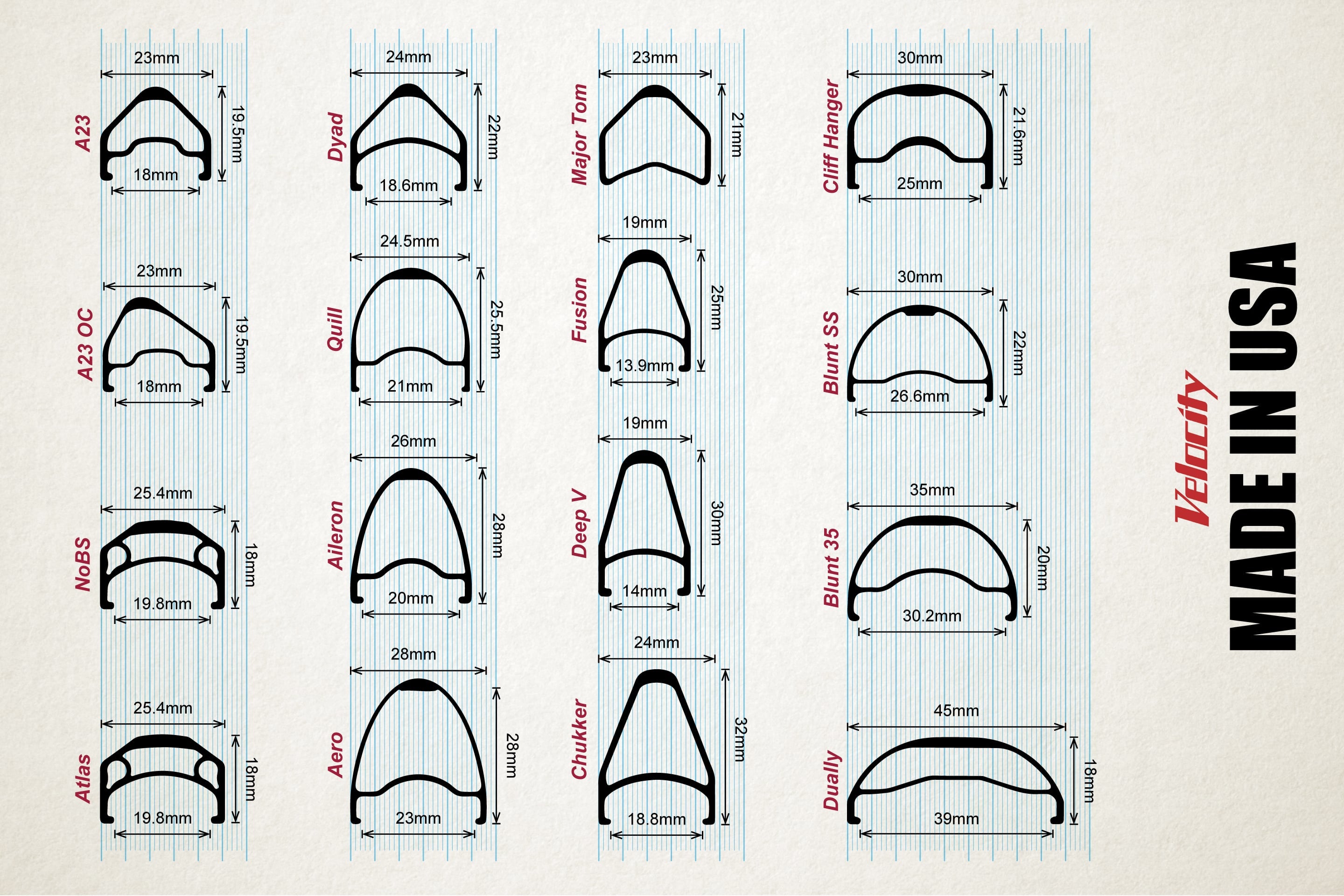

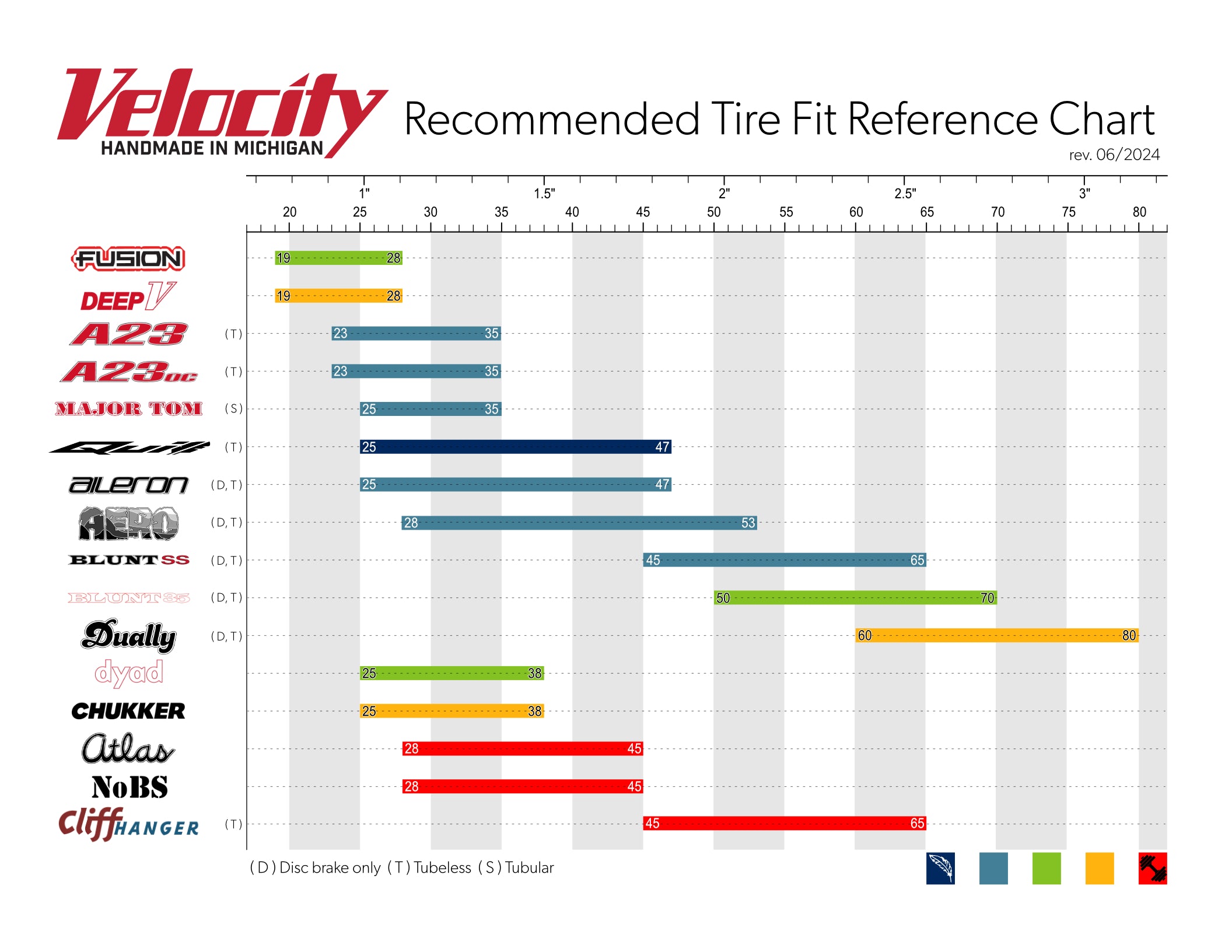

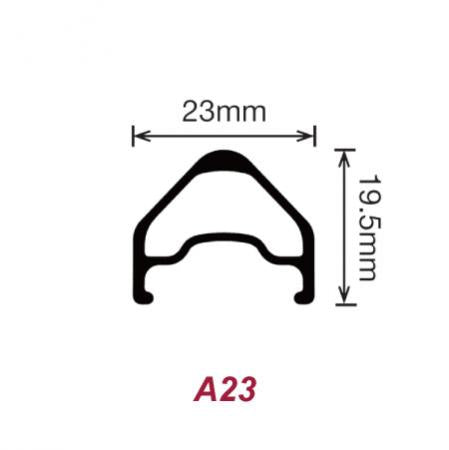

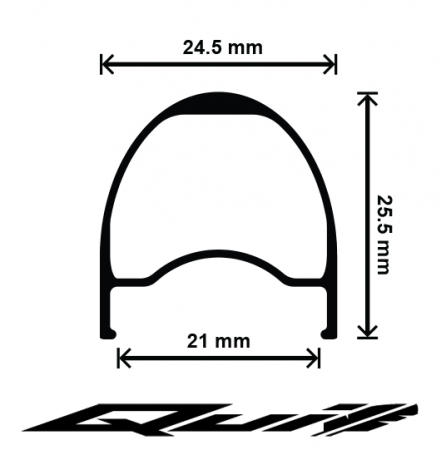

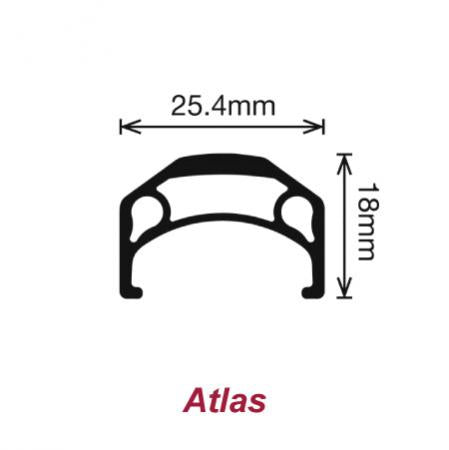

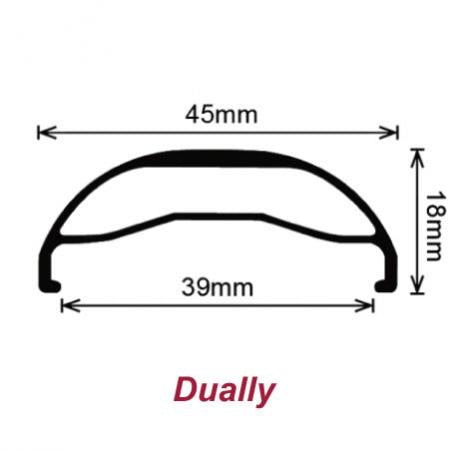

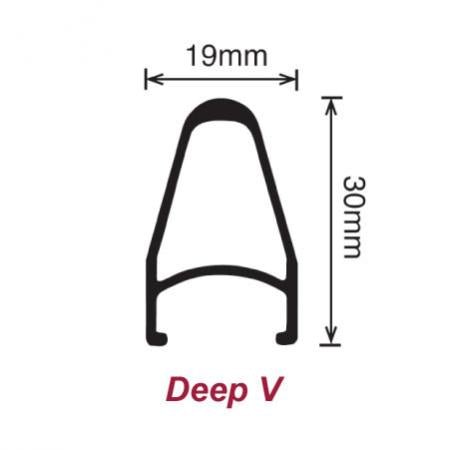

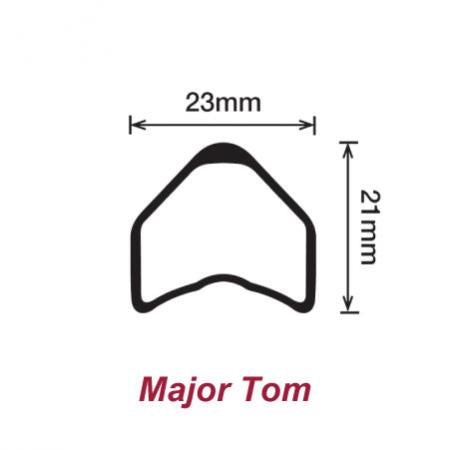

Velocity Rim Collection

-HUB TECHNOLOGY-

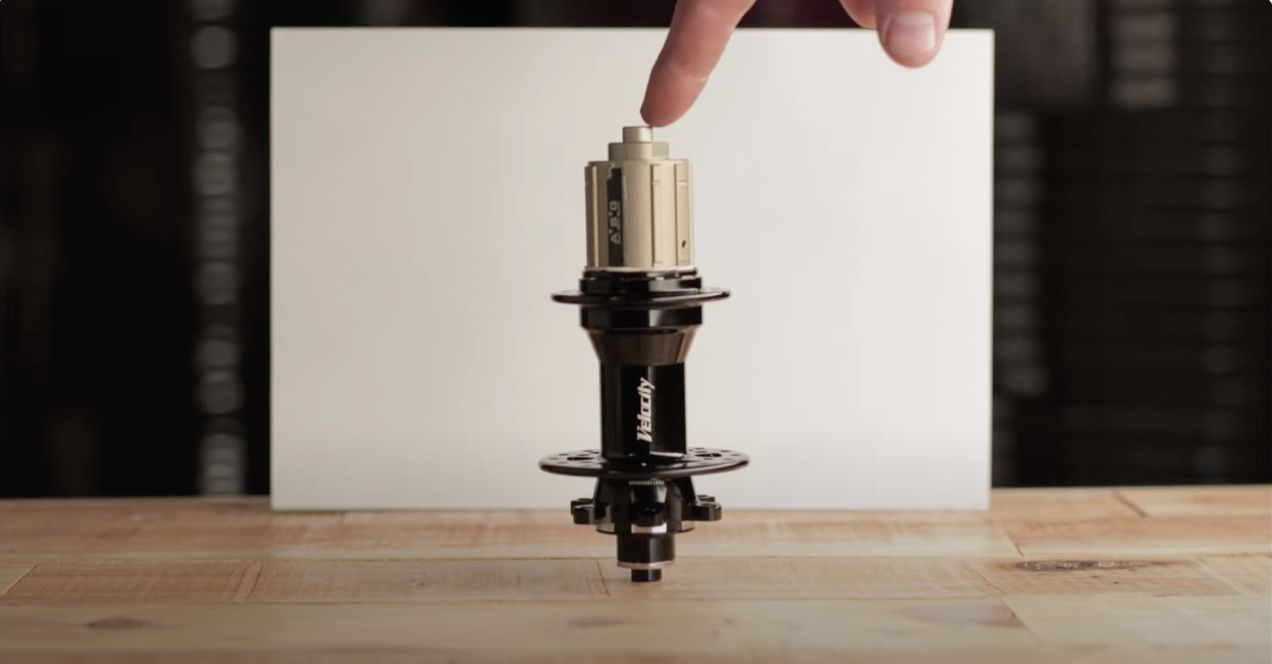

Convertible Hubs

Sportbike technology is evolving rapidly. At least three front axle standards and two rear axle standards exist.

Velocity's convertible hubs accommodate all of them, eliminating the need to swap hubs as technology evolves.

The convertible disc front hub includes all the parts needed to switch between 9mm quick release, 12mm through-axle, and 15mm through-axle standards.

Drivers are available in Shimano and XD. Convertible hubs are available in 100mm front, 135/142mm rear, 110mm front and 142mm rear with Boost spacing, 157mm rear with Super Boost, and 150mm front, 170/177mm rear or 197/190mm for fat bikes Available in.

*Convertible mountain disc hubs cannot be converted to mountain rear and Boost or Boost and Super Boost.

Sealed bearing

Cartridge bearings with weatherproof seals are used in most Velocity hubs. Race hubs are designed with cyclocross in mind and feature improved double bearing seals for greater weather resistance.

Sealed does not mean waterproof. If the bearings are immersed in water or subjected to high-pressure washers or invasive cleaning, service or replacement by a professional mechanic is recommended.

Bearing preload is set at the factory and does not need to be adjusted. All Velocity sealed cartridge bearing hubs come standard with an internal cam type quick release.

Quick Release

Internal cam quick releases offer several advantages over external cam quick releases.

Because the entire tightening mechanism is contained within the lever, the moving parts are cleaner and more effective. This reduces the force on the lever and allows greater tension to be applied to the dropout. Internal cam quick releases are a necessity when mounting wheels on chrome or stainless steel dropouts. The quick release is included with all sealed cartridge bearing hubs.

Cassette Body Maintenance

The cassette body pawl is what transfers your power to the ground. They should be inspected and relubricated at least once a year, depending on usage and environment.