A.Dugust

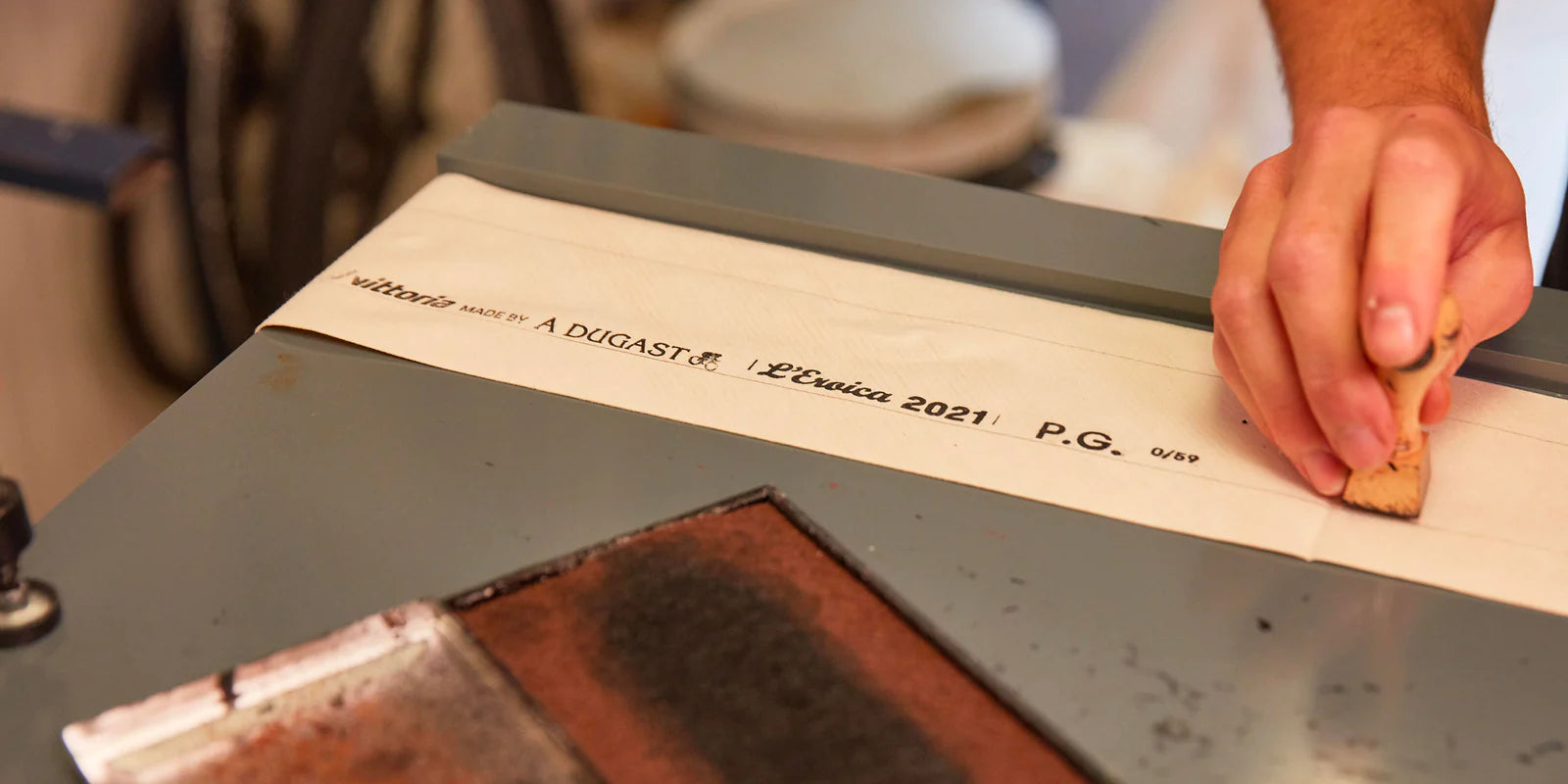

Founded in 1972 by André Dugas, this brand of handmade tires is made using the hand-sewn method. Today, the brand is produced in the Netherlands by Richard Nieuweis, who has inherited the company name and technology. Richard travels to all kinds of bicycle race tracks around the world to get feedback from the top riders, which he incorporates into his product development. Dugas is not just "handmade" because it is good. Dugas tires are made using a manufacturing process that carefully selects materials and takes advantage of the "supple ride" characteristic of natural materials, and the unique ride quality has earned the support of many world champions. Latex tubes are used for the inner tubes of all tires to ensure that the ride quality is not compromised.

Beginning in 2021, Dugas has expanded production to Thailand, home to Vittoria's world-class manufacturing facility, seamlessly blending traditional craftsmanship with cutting-edge technology. Thai craftsmen will absorb Richard's valuable knowledge and continue the tradition of excellence in the manufacture of A.Dugast tires. This important step ensured that the spirit of A.Dugast was carried on, resulting in a carbon-neutral production facility that is both Thai craftsmanship and environmentally friendly.

TECHNOLOGY

Neoprene Coating

Invented by A.Dugast and used for the first time, Neoprene Coating is a special protective coating applied to A.Dugast tires to prevent the tire casing from absorbing moisture and mud and to extend its life. The Neoprene Coating is a 0.1 mm thick silicone layer that is brushed onto the tire casing and fills the open spaces in the threads.

This coating prevents water and mud from penetrating the casing and prevents the casing material from being degraded by powerful cleaners. Thanks to the neoprene coating, Dugast tires are easy to clean and long-lasting. More importantly, the coating does not affect the tire's function or comfort.

It is important to wash the tubulars after use (with water and/or soap, but not with aggressive products) and dry them at room temperature (approx. 20°C).

New Material Monsoon

It is a high-performance compound that improves the performance of every element required in a tire tread: reduced rolling resistance, increased grip, and improved puncture resistance and durability.

Dugas has been using the Monsoon in its Typhoon, Rhino, and Pipisquallo cyclocross tires, and has been testing it repeatedly since last season in partnership with the top CX racers. Tests have resulted in feedback of lower rolling resistance, more grip, and improved performance compared to conventional treads. This specifically means that the same driving feel can be achieved at one higher pressure setting than the usual setting. This translates into the advantage of a lower risk of punctures.

Adhere the tire.

- Inflate the tire to 0.5 to 1 bar and install it on a new rim without adhesive. Be sure to place two fingers on the base tape, one on each side of the valve, and press the tread side valve leg with your thumb.

- Polish the rim with coarse sandpaper.

- Place a thin layer of adhesive on the rim.

- Allow this to dry for 24 hours.

- Place a second thick layer of adhesive over the entire rim.

- Allow it to dry again for 24 hours.

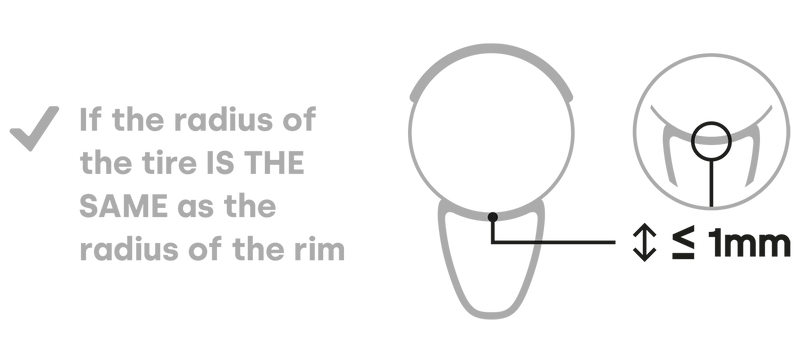

- Check to see if the radius of the tire is the same as the radius of the rim

- And be sure to check the following notes

- Remove the tire from the rim and check the air pressure (0.5 to 1 bar).

- Apply a thin layer of adhesive to the base tape of the tire.

- Place a layer of adhesive on the rim.

- Place the tire on the rim. After applying the base tape, the tire must be mounted on the rim within 15 minutes. Note: The wheel must always be kept in the upright position with the valve hole at the top. Next, place the tire on the rim. Push the tire in from above first (always with the same force!). Do not push the wheel backwards. Turn the wheel over and pull the last part of the tire onto the rim.

- Inflate the tire to about 2 bar.

- Center the tire until the tread is in line with the wheel.

- Control whether the base tape appears on both sides of the rim. If not, push the tire slightly so that the base tape is even on both sides of the rim.

- Remove any adhesive still remaining between the tire and rim with a towel. Be careful not to use gasoline or other chemicals.

- Allow everything to dry for 24 hours. Place another layer of adhesive and press a small piece of rim tape into the adhesive. Note: The tape must not be too wide (only between 6 and 9 mm).

- Allow everything to dry for 24 hours.

- Place another layer of adhesive and press a small piece of rim tape into the adhesive. Note: The tape must not be too wide (only between 6 and 9 mm).

- Allow everything to dry for 24 hours.

- Place another layer of adhesive on top of the tape.

- Allow everything to dry for 24 hours.

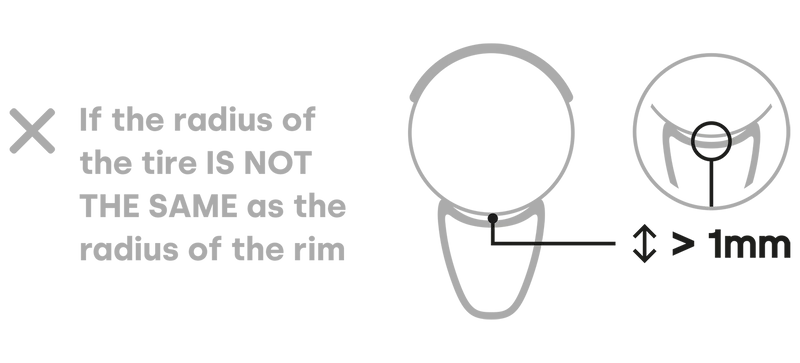

- Check again if the radius is the same as the radius of the rim. If yes: continue to the left side of this page. If no:.

- - Is the gap between the rim and the tire less than 0,5 mm?

- Place one layer on the rim and let it dry for 24 hours

- - Is the space between the rim and tire more than 0,5mm?

- Repeat from the first step

About the base tape

With the use of disc-braked wheels and larger tires becoming increasingly common, A Dugast offers cross tires with wider base tapes for a better fit with larger rims.

The larger base tapes provide additional protection against tubular sidewalls.

Dugast is available in three different base tape widths

- Small basetape (maximum width 23 mm, for rims up to 27 mm)

- Large base tape (for rim widths from 23 mm to 27 mm)

- Extra large base tape (for rim widths from 27 mm to 32 mm)

Precautions for use

The neoprene coating is very thin and does not affect the functionality or comfort of the tubulars, but maintenance is essential for long-term use.

- It is important to always wash the tubulars with water and detergent after use.

- However, oil-based cleaners such as degreasers should not be used.

- After washing, dry them indoors away from ultraviolet rays.

Of course, it is possible to protect the tire sides with Aquasure. If tires are not washed after use, Aquasure is recommended.

Install clincher tires

tubeless setup

A. The Dugast clincher is made of 100% cotton and we strongly recommend that you follow these instructions carefully to avoid air bubbles under the tread.

Note: This is a 100% cotton casing product.

- Installation methods differ from other companies. .

Please read these instructions carefully to avoid air bubbles under the tread. - Use only ammonia-free sealant.

Make sure your rim is the correct size for your tire before installation. - If you are unsure, please contact us.

Remove any debris or old sealant from the inside of the rim. 2.

2. use high quality tubeless rim tape suitable for tubeless tires and for the air pressure indicated on the tire.

3. insert the tubeless valve until the rubber base rests firmly and evenly on the rim tape.

4. after checking the direction of wheel rotation, install the two beads on the rim, making sure that all beads are seated at the bottom of the rim profile.

*Tyre rotation: the tire knob must always be correctly oriented in the direction of travel.

5. inflate the tire slowly to a maximum of 1 bar. The bead does not need to be snug against the rim 6. Remove the valve core using the valve tool. Inject the appropriate amount of sealant through the valve stem and reinstall the valve core. 6.

6. slowly inflate the tire again to a maximum of 1 bar. Carefully push the tire inward where it is not in the correct position so that the sealant is spread over the entire tire between the bead and the rim. The sealant will help lubricate the tire as you twist it to move the bead into its final position. Do not inflate to more than 1 bar! Do not inflate the tire to more than 1 bar.

7. if the tire is properly seated, slowly inflate to 1.5 bar. Rotate the wheel in all directions to ensure an even application of sealant.

* Never allow the wheel to bounce.

MAINTENANCE : Store in a dry place at room temperature, away from light. After every ride, be sure to remove all particles from the tread that could damage the casing, such as pebbles, glass, metal, etc. Tires should be washed in fresh water. Even if not used for an extended period of time, keep the valve in the upper wheel position and slightly inflated to prevent clogging of the valve. Rotate the wheel occasionally to ensure that the sealant is evenly distributed throughout the tire.

A.Dugust Collection

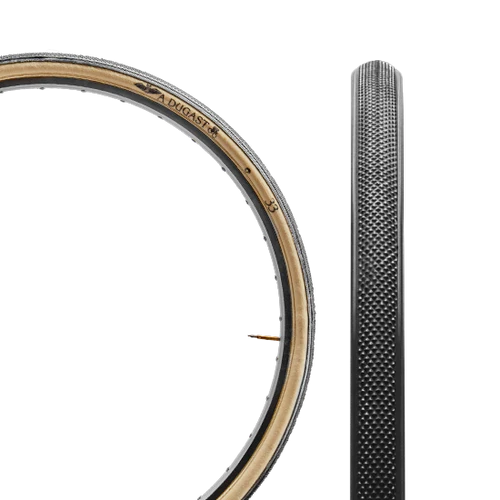

Typhoon Tublar & Clincher

An all-purpose competition tire. Thanks to the radius control feature integrated into the sides of the tire, the tire cuts through unpaved curves. The specially designed tread provides excellent grip in all conditions and is available only from Dugast.

SHOP

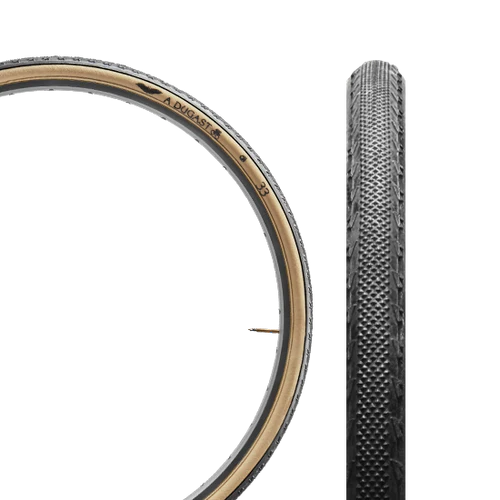

Rhino Tublar & Clincher

Competition tire for muddy courses.

Tread with very high knobs for excellent grip.

Open tread design allows mud and debris to be ejected instantly, reducing rolling resistance.

Pipistrello Tublar & Clincher

Competition tire for muddy courses.

Tread with very high knobs for excellent grip.

Open tread design allows mud and debris to be ejected instantly, reducing rolling resistance.

Pipisquallo Tublar & Clincher

Competition tire for muddy courses.

Profile with very high studs for very good grip. The design of the profile helps to loosen mud. Despite the open structure of the profile, the rolling resistance of the tube is low.

A.Dugast Accessories

All the accessories you need for your dugas are here.

SHOP