Testing

Light and durable

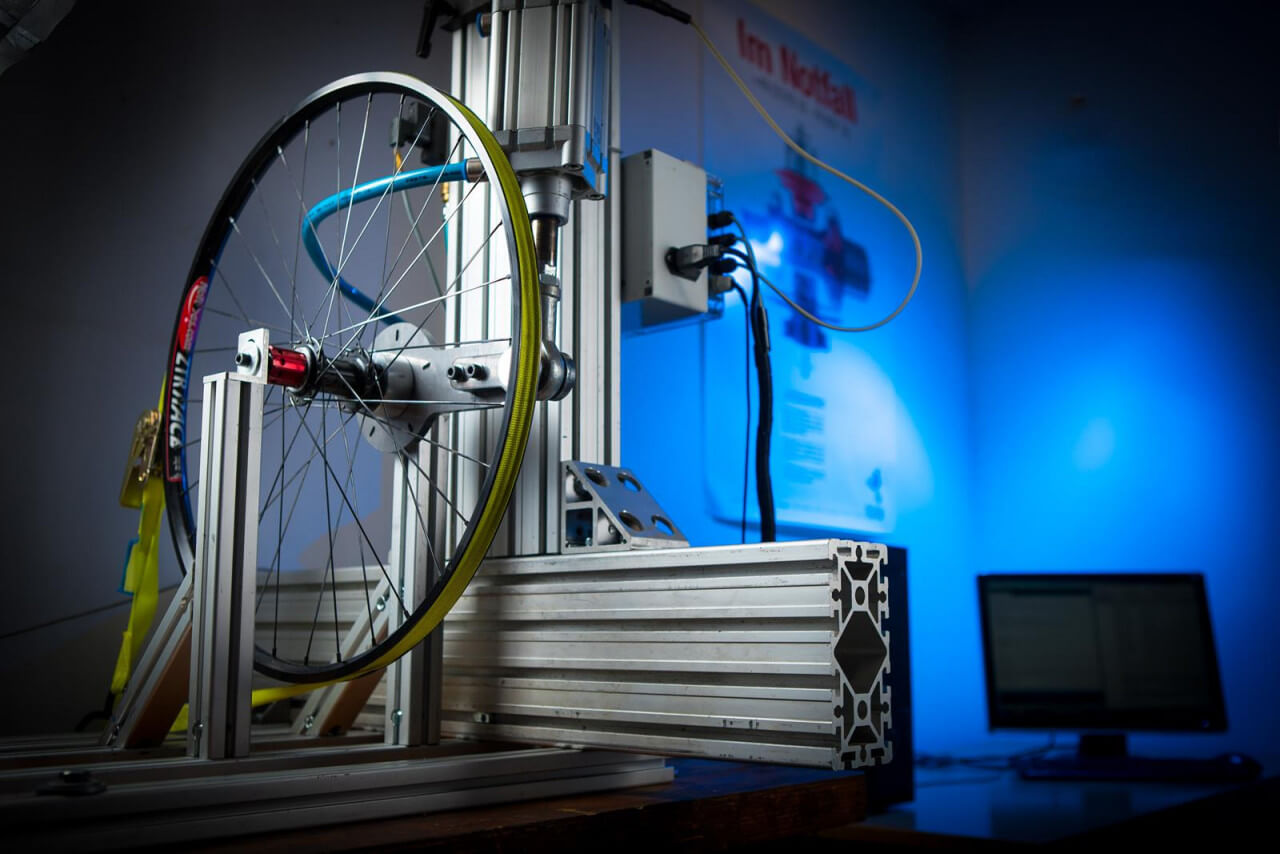

Designing a lightweight, durable product is much more difficult than it sounds. In the early conceptual stages, care must be taken to ensure even stress distribution and load-optimized geometry. Even with the latest software available, it is impossible to know how a part will behave under repeated loading until you actually test your idea on a test bench. To accelerate product development, TUNE has multiple test stands and conducts almost any test in-house.

All products are rigorously tested in the laboratory and on actual rides before they are offered to customers for production. This involves a lot of time and work, but at the same time we recognize that it is our minimum obligation to ensure the highest safety standards and peace of mind for our customers.

Bench test procedure

TUNE bench testing is used to investigate the fatigue behavior of components. A defined number of cycles of dynamic loading is applied to the test part to simulate regular product use over several years. The required forces and loading cycles are defined in bicycle-specific test procedures as they are all defined in the bicycle-specific test procedures. In some cases, these procedures may not cover each component of the bicycle or meet TUNE's safety requirements. Therefore, TUNE has developed its own testing procedures and testing facilities. The know-how thus gained helps TUNE to continuously improve its products and testing procedures.