Sustainability

Mother nature

TUNE's roots are in one of Germany's most beautiful landscapes, the Schwarzwald, where TUNE has been based since its founding 30 years ago. The proximity to this beautiful landscape has definitely influenced the products TUNE produces on a daily basis.

Solar power system

A large part of the roof of the headquarters in Buggingen is covered by a solar power system that generates up to 21 KW of electrical energy. This system is capable of covering approximately 50% of the TUNE factory's energy consumption.

On weekdays, 100% of the energy generated is used to run the machines and for general operations, and on weekends, the electricity produced by the system is connected to the local power grid to provide green energy.

Solar power system

A large part of the roof of the headquarters in Buggingen is covered by a photovoltaic system that generates up to 21 KW of electrical energy. This power generation system can cover approximately 50% of the TUNE plant's energy consumption.

On weekdays, 100% of the energy generated is used to run the machines and for general operations, and on weekends, the electricity produced by the system is connected to the local power grid to provide green energy.

Production waste

Milling and turning operations generate large quantities of metal chips. These chips are a valuable resource and can be recycled and used as raw material again. To facilitate their recycling, the chips are correctly sorted by variety and returned to the raw material cycle again by local companies.

From the processing of TUNE's aluminum products, no non-recyclable waste TUNE is proud to say that no non-recyclable waste is produced from the processing of its aluminum products.

Product packaging

TUNE's product packaging has become simpler and more minimalist over the years. In the past, we have used plastic pressure-seal bags that can be used as packaging and then used for storage of all types of goods, but we are currently in the process of restructuring our product packaging to completely eliminate the use of plastic. The plastic pressure-seal bags will be replaced by an equivalent solution made of paper.

We are also researching more environmentally friendly labels for our packages. Grass-based paper mixed with recycled paper is one viable option.

Shipping packaging

If you have already received a package from TUNE, you may have noticed that the boxes are used, not manufactured by TUNE. like many other brands, TUNE receives many deliveries daily, and we try to reuse those boxes for shipping. This eliminates the need for new boxes and reduces cardboard waste.

TUNE encourages customers to reuse the boxes they receive from TUNE as much as possible to reduce their impact on the environment.

Products

To become a leader in carbon products that enable recycling, Skyracer saddles, for example, are the only saddles in the world that use a thermoplastic carbon matrix. Compared to typical thermoset products, thermoplastic matrices are recyclable. We are also researching ways to reduce the CO2 emissions of carbon products by using natural fibers in conjunction with carbon.

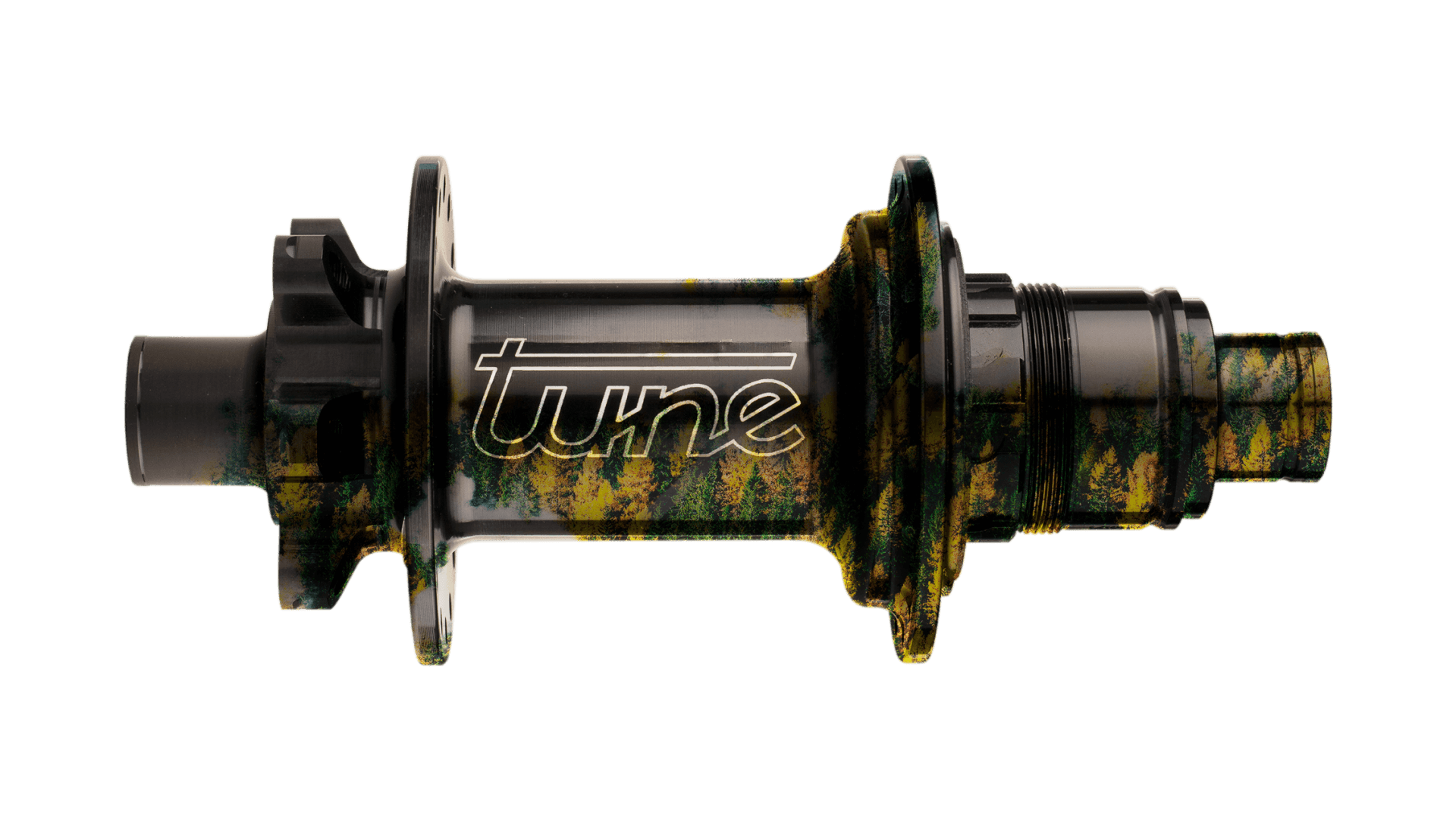

TUNE's aluminum products are also extremely environmentally friendly. Due to their modular design, the hubs manufactured by TUNE are designed to correctly conform to a variety of different standards, so they can be used for a long period of time, even as standards continue to change. To further extend their service life, TUNE also provides spare parts for the long term.