Why hand-assemble the wheels?

More Better Wheels.

Changing the wheel can drastically change the ride of a bicycle and show the pilot a new world.

We hope that you who have arrived at this page will ride not a crest-shaped, fully assembled wheel, but a better wheel that is assembled reflecting the will of the rider and the assembler.

Infinite combinations

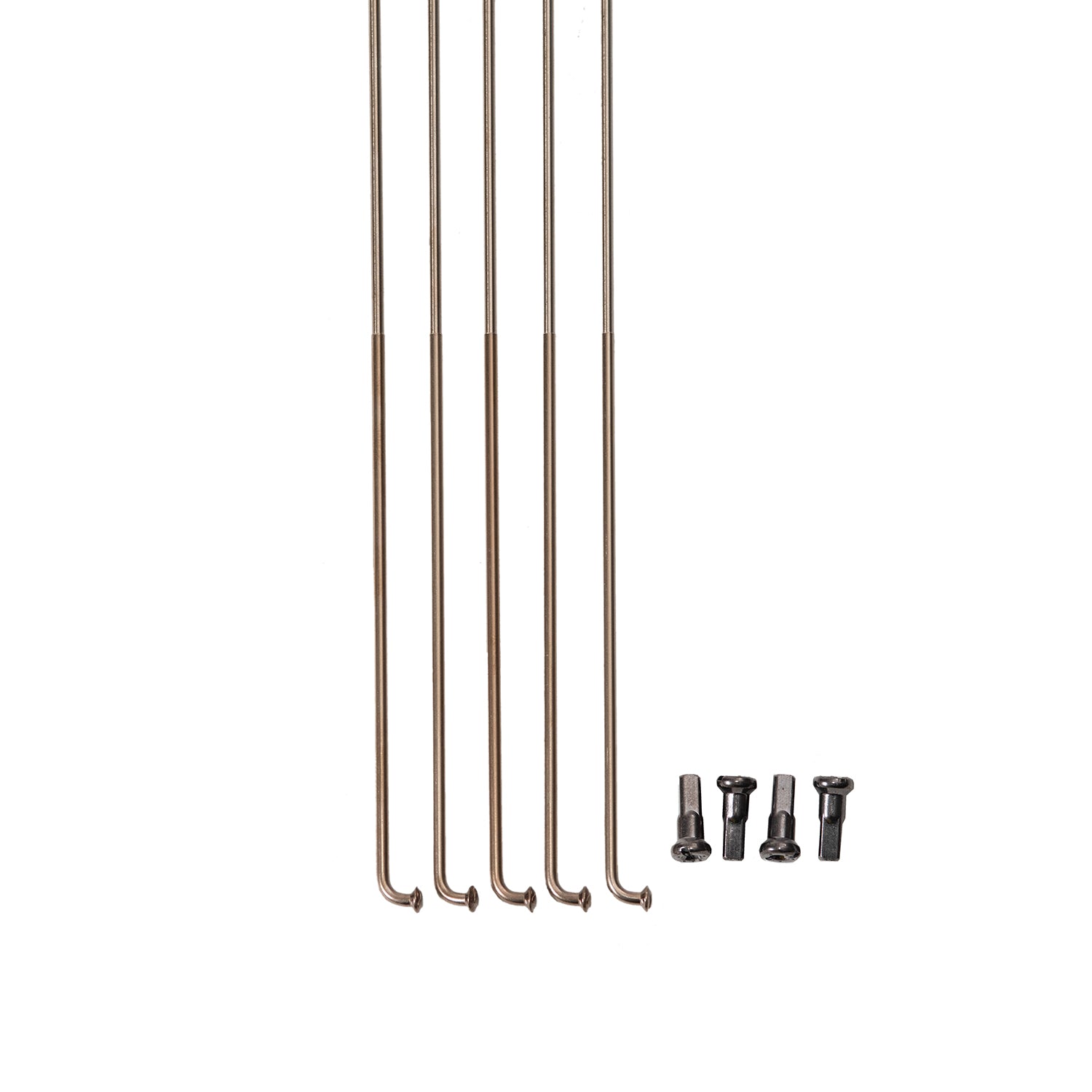

A hand-assembled wheel can be created in an infinite number of combinations of nipples, spokes, hubs, and rims. Because of the infinity, we often get lost, and because we seek perfection, we are unable to choose anything. Gorillaspan offers wheels that are better than the wheels you have now, and we want to be there for you.

insist on one's own ideas

The advantage of assembling each wheel by hand is that the will of the rider resides in the wheel. The appearance, turning power, and weight of the new wheel are different for everyone, but when the will of the rider and the will of the assembler are combined, a better wheel than the current one is born.

Choose parts and assemble your own wheels!

Price: Total of parts + wheel assembly labor (¥5,000 per wheel) + shipping (¥2,000, excluding islands)

*When parts are brought in, wheel assembly labor is ¥7,000 per wheel.

Choose from a selection of stock wheels

This is a collection of stock wheels assembled by Gorilla Span. Let's start with the wheel size that fits your current bicycle and then choose the wheel size that best suits your application.

29" & 700c

We have compiled a list of basic size 700c road and gravel bikes, as well as 29" wheels that are often used by dirt tourers.

There are surprisingly few complete 29" wheels, a genre in which Gorillaspan really comes into its own.

27.5 & 650B

This category has wheels for a wide range of uses, including gravel riding, touring, and daily commuter. Choose according to lightness, sturdiness, use, and riding style.

View Collection

26inch

Old mountain bikes inherited from family members, and those who want to upgrade the suspension of their old bikes and continue to ride them are in this category.

It is no exaggeration to say that there are no fully assembled 26" wheels, so this is a good opportunity to show your hand-assembly skills.

Other / Dynamo, etc.

We can provide any kind of wheels for small diameter vehicles, cargo bikes with different diameters front and rear, hub dynamos, etc. Please use our contact form.

How to build Gorilla Spun